(1) What is a built-in electric drum

As the name suggests, a built-in electric drum is a way of installing a motor inside the electric drum. Similarly, it can be seen that the motor of the externally mounted electric drum is located outside the drum.

(2) The advantages of built-in electric drum

There are many advantages to the built-in electric drum, such as compact structure, clean appearance, easy cleaning, and simple installation. In the later use process, it can also reduce energy consumption and thus lower costs. The motor is located inside the roller, making the components less prone to damage and extending their service life.

(3) Application of built-in electric drum

The built-in electric drum can be applied to various occasions. Among them, the food processing industry is particularly popular. Because the food processing industry has high requirements for hygiene environment, the use of built-in electric rollers can effectively solve this problem!

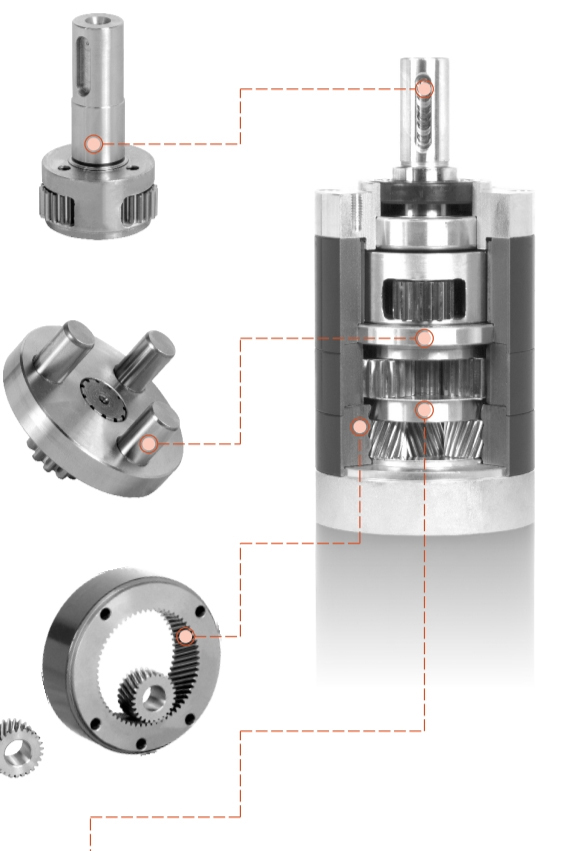

Electric drum is a new type of driving device that combines a motor and a reducer inside the drum body. It is mainly used in fixed and mobile belt conveyors, replacing traditional electric motors, and as a separate drive device for reducers outside the driving drum.

Electric drum has many advantages such as compact structure, high transmission efficiency, low noise, long service life, smooth operation, reliable work, good sealing, small space occupation, easy installation, etc., and is suitable for working in various harsh environmental conditions. Including damp, muddy, and dusty working environments.

Common causes of unstable electric drum

The instability of electric drum can generally be caused by various factors, including mechanical failure, electrical problems, bearing damage, motor failure, reducer problems, unstable power supply, and so on. Understanding these common unstable factors is crucial for ensuring the normal operation and safety of electric rollers.

mechanical failure

Mechanical failure is a common factor that causes instability in electric rollers. The wear, damage, or aging of components such as the drum body, bearings, and gears can all lead to unstable operation of the drum. For example, when the bearing is severely worn, it may produce abnormal noise, overheating, and even cause the drum to fail to rotate normally.

Electrical issues

Electrical issues are also a significant factor contributing to the instability of electric rollers. Unstable power supply, poor circuit connection, motor damage or overload may all affect the normal operation of the electric drum. The fluctuation of power supply voltage may cause instability in the speed and torque of the electric drum, and it is necessary to adjust or replace the power supply in a timely manner.

Bearing damage

Bearings are important supporting components in electric drums, and if the bearings are damaged, the stability of the electric drum will be affected. When the bearing is severely worn or has abnormal noise, overheating, etc., the bearing 1378 should be replaced in a timely manner.

Motor malfunction

The core component of an electric drum is the motor, and the failure of the motor directly affects the operation of the drum. Motor faults include overheating, abnormal noise, odor, etc. It is necessary to replace the motor in a timely manner to restore the normal operation of the drum.

Gearbox issue

The reducer is an important transmission component in the electric drum, which functions to reduce the output speed of the motor to meet the speed requirements of the conveyor belt. Problems with the reducer, such as gear damage, bearing wear, etc., can affect the stable operation of the electric drum.

Unstable power supply

Unstable power supply, such as voltage fluctuations, frequent power outages, etc., can cause unstable operation of the electric drum. It is necessary to inspect and adjust the power circuit to ensure its stable supply of 28.

How to ensure the stability of electric drum

summary

Ensuring the stability of the electric drum involves multiple aspects, including correct assembly, selection of appropriate accessories, power management, structural design, maintenance, etc.

Correct assembly

Correct assembly is the foundation for ensuring the stability of the electric drum. The drum needs to be installed horizontally and perpendicular to the conveyor frame. All accessories need to be installed in the prescribed manner to prevent the shaft end from moving or deforming 310.

Choose appropriate accessories

Choosing appropriate accessories such as motors, reducers, drum bodies, bearings, and sealing rings is crucial for the stability of the drum. The material of the drum body is usually stainless steel or other corrosion-resistant materials to adapt to different working environments.

Power management

The power supply is the foundation for the operation of the electric drum. It is necessary to ensure the voltage and current stability of the power supply circuit, and check whether the circuit is firmly connected and whether there is any short circuit or open circuit. Ensure voltage stability by adjusting the excitation circuit magnetic field or using magnetic pole washers, etc.

Structural Design

The structural design of the electric drum has a significant impact on its stability. The drum body is usually equipped with bearings inside to support the rotation of the drum and drive the conveyor belt to move through the friction between the drum surface and the conveyor belt. The related components of the drum, such as end caps and bearings, need to be regularly inspected and maintained.

Maintenance and upkeep

Electric rollers require regular maintenance and upkeep to ensure their normal operation and safety. The maintenance includes cleaning and lubricating the moving parts of the drum and bearings, checking the wear of the drum and bearings, and replacing them if necessary